| Antal | Længde (mm) |

|---|

Erik Larsen & Søn | Din eneste officielle og autoriserede LINDAPTER DISTRIBUTØR i Danmark

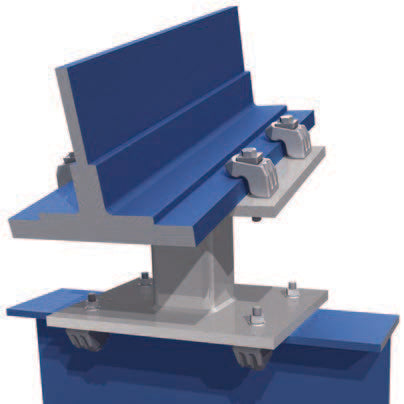

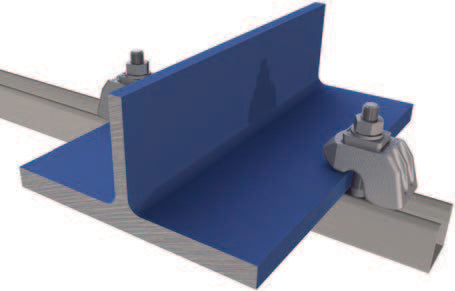

Lindapter Type AAF - Bjælkebeslag

TILSKÆRING AF SKINNER OG RØR!

OBS! Hvert skær tager 3 mm af længden. 1. Klik på knappen "Tilføj". 2. Angiv antal og den ønskede længde (Klik igen på knappen "Tilføj", hvis du vil tilføje yderligere antal/længder). 3. Klik derefter på knappen ”Udregn”. Antallet opdateres herunder. 4. Klik tilsidst på ”Tilføj til kurven” knappen. Antal udskæringer og længder tilføjes til din kurv.

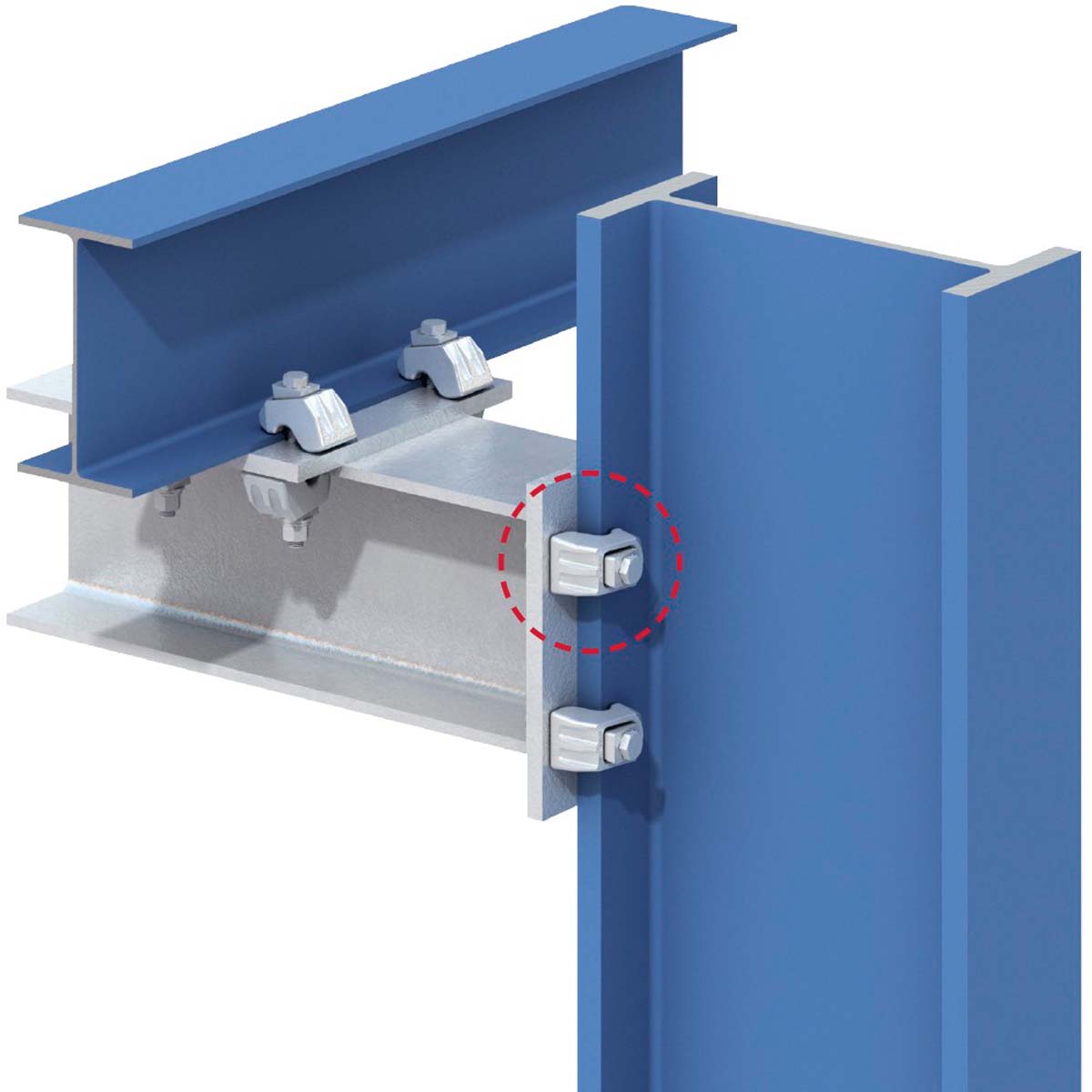

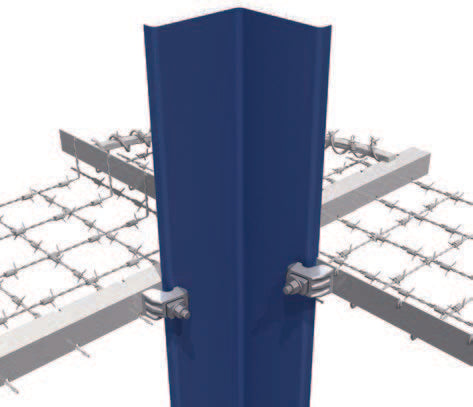

Lindapter Type AAF bjælkeklemmen (Girder Clamp) er et CE-mærket bjælkebeslag til høj belastning. Bruges til at samle to stålbjælker uden brug af svejsninger.

NB! Bolt og møtrik til fastgørelse sælges separat.

Fås i varmgalvaniseret.

Type AAF variantoversigt

| Type | Bolt | Bæreevne | Spændings- moment* Nm |

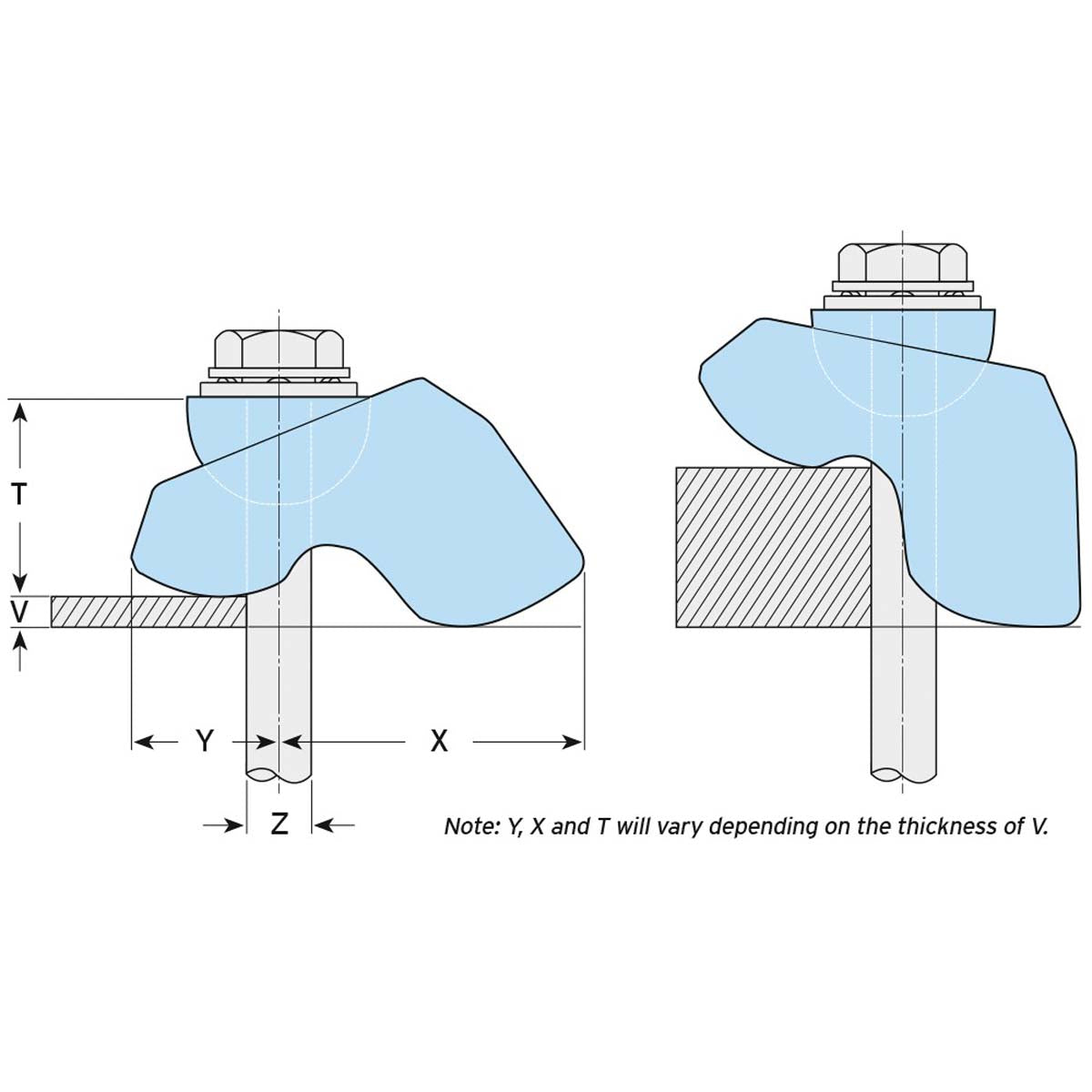

Dimensioner | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Z | Klasse4 | Træk/ 1 bolt kN (SF 4,5:1) |

Friktion1/2 bolte kN (SF 2:1) |

Flangetykkelse3 V mm |

Y mm |

X mm |

T mm |

Bredde mm |

|||

| malet stål2 | galv. stål | ||||||||||

| AAF M12 | M12 | 8.8 | 8,5 | 3,4 | 3,9 | 90 | 5 - 26 | 25 - 34 | 27 - 49 | 26 - 35 | 41 |

| AAF M16 | M16 | 8.8 | 16,0 | 8,0 | 10,0 | 240 | 6 - 30 | 34 - 50 | 31 - 58 | 35 - 46 | 56 |

| AAF M20 | M20 | 8.8 | 26,3 | 13,0 | 16,0 | 470 | 6 - 40 | 48 - 78 | 49 - 64 | 52 - 64 | 77 |

| AAF M12 | M12 | 10.9 | 10,0 | 4,0 | 5,2 | 130 | 5 - 26 | 25 - 34 | 27 - 49 | 26 - 35 | 41 |

| AAF M16 | M16 | 10.9 | 19,5 | 11,0 | 12,0 | 300 | 6 - 30 | 34 - 50 | 31 - 58 | 35 - 46 | 56 |

| AAF M20 | M20 | 10.9 | 30,0 | 20,0 | 25,0 | 647 | 6 - 40 | 48 - 78 | 49 - 64 | 52 - 64 | 77 |

*Spændingsmomentet er baseret på ikke-smurte bolte. SF = sikkerhedsfaktor.

1Glidemodstandsværdierne er beregnet mod glidning/bevægelse over 0,1 mm. 2Pulverlakerede og malede overflader. 3Afstandsskiverne AFP1 og AFP2 kan benyttes til større flangetykkelser (kun for AAF12 og AAF16). 4Lindapter anbefaler høj-styrke samlinger i henhold til EN14399-1, når 10.9 bolte anvendes.

Lindapter Type AAF svejsefri bjælkeklemme

Type AAF-bjælkeklemmen bruges til at opnå en hurtig samling af stålsektioner i en styrke, der kan håndtere høje belastninger i form af trækbelastning, slipmodstand eller kombinerede belastninger.

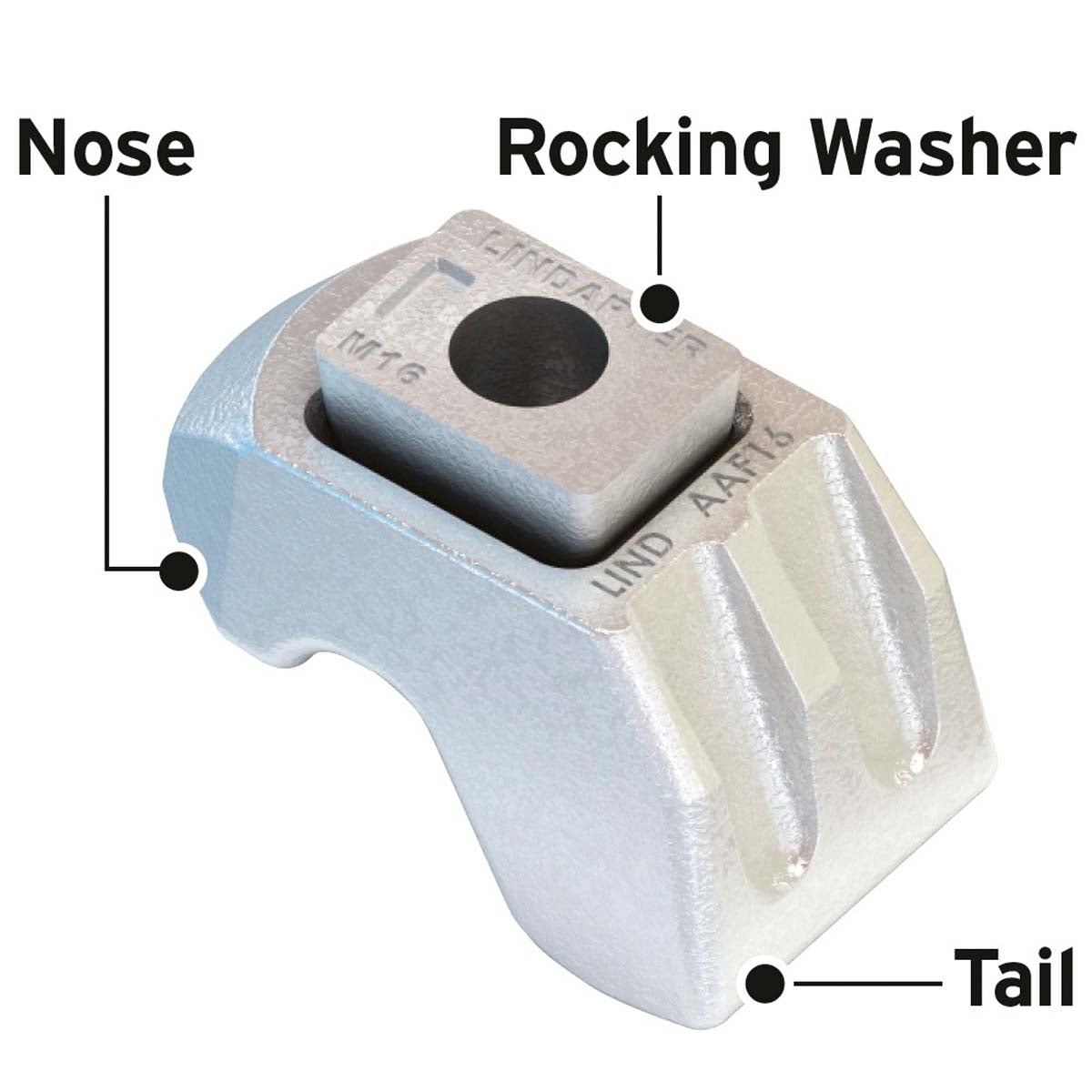

Fastspænd Type AAF bjælkebeslaget med bolt og møtrik. Beslaget består af en klemme og en bevægelig spændeskive, der gør det muligt at tilpasse klemmen, så den passer til flere flangetykkelser.

Lindapter Type AAF installationsvideo

Det er nemt at samle konstruktionsbjælker med bjælkeklemmerne fra Lindapter. Se installationsvideoen herunder.

Fordele

Lindapter bjælkeklemmer har en høj sikkerhedsfaktor på 5:1 og en række afgørende fordele: Du har ikke brug for specialudstyr til samlingen, bæreevnen bliver ikke forringet, og du undgår at svejse og i mange tilfælde også at bore on-site. Du bruger blot en momentnøgle til at stramme bolte og/eller møtrikker til et passende moment og korrekt tilspænding.

- Ingen boring eller svejsning

- Hurtig og effektiv samling af bjælker

- Flere uafhængige godkendelser

- Nem justering on-site

- Svækker ikke konstruktionen

- Gratis tegning og beregningshjælp